When an inverter fan is not working, it can lead to a series of problems that affect the normal operation and service life of the inverter. The specific impacts are as follows:

1. Overheating of the Inverter

Core Issue: The fan is the main component responsible for dissipating heat inside the inverter. If it stops working, the heat generated by components such as power semiconductors (IGBTs, MOSFETs) and capacitors cannot be effectively dissipated.

Consequences:

The internal temperature of the inverter will rise rapidly, exceeding the safe operating temperature range (usually 40–50°C).

High temperatures can cause thermal stress on components, leading to accelerated aging, reduced service life, or even immediate damage (e.g., capacitor explosion, semiconductor burnout).

2. Inverter Protection Activation

Built-in Safety Mechanism: Most inverters are equipped with overheat protection functions.

Reactions:

When the temperature sensor detects excessive heating, the inverter will trigger an alarm (e.g., displaying an “OVER HEAT” fault code).

In severe cases, the inverter will automatically shut down to prevent permanent damage, resulting in sudden 停机 (shutdown) of the connected equipment (e.g., air conditioner, motor).

3. Reduced System Efficiency and Performance

Impact on Operation:

Even if the inverter does not shut down immediately, overheating will cause the control system to reduce output power (derating) as a protective measure.

For example, an inverter-driven air conditioner may exhibit reduced cooling capacity, and a motor may have decreased torque or speed instability.

Energy Waste: Inefficient heat dissipation can also lead to increased power loss within the inverter, reducing overall energy conversion efficiency.

4. Collateral Damage to Connected Equipment

Indirect Effects:

If the inverter powers a motor, unstable operation due to overheating can cause voltage/current fluctuations, potentially damaging the motor or other connected loads.

In photovoltaic (PV) systems, a faulty inverter fan can reduce power generation efficiency and even cause the entire PV array to stop working.

5. Potential Safety Risks

Fire Hazard: Prolonged overheating may cause insulation materials inside the inverter to melt or ignite, especially in dusty or flammable environments.

Electrical Shock Risk: Damaged components may lead to insulation failure, exposing live parts and increasing the risk of electric shock.

6. Costly Repairs and Downtime

Maintenance Implications:

Replacing damaged components (e.g., IGBT modules, capacitors) can be expensive, especially for high-power inverters.

Downtime caused by repairs can lead to production losses in industrial settings or discomfort in residential applications (e.g., air conditioning failure).

Common Causes of Inverter Fan Failure

Understanding the root causes can help with troubleshooting:

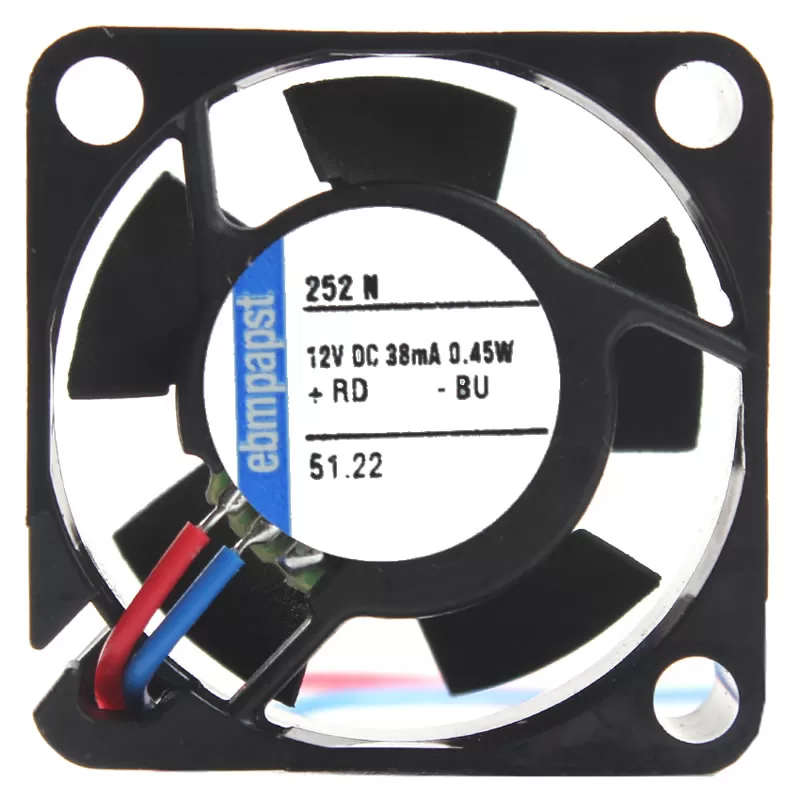

Mechanical Issues: Dust accumulation, debris jamming the fan blades, or bearing wear.

Electrical Problems: Fan motor burnout, faulty wiring, or a failed fan control circuit.

Environmental Factors: High ambient temperatures, excessive humidity, or exposure to corrosive gases.

Component Aging: Long-term operation leading to fan degradation.

Recommended Actions When the Fan Fails

Immediate Shutdown: Power off the inverter to prevent further damage.

Inspection: Check for dust accumulation, fan blade obstruction, or obvious physical damage.

Troubleshooting:

Test the fan motor with a multimeter to see if it is powered or burned out.

Check the fan control circuit and fuses.

Professional Repair: If internal components are damaged, contact a qualified technician for replacement (e.g., fan, control board).

Preventive Maintenance: Regularly clean the inverter and replace fans according to the manufacturer’s recommendations to avoid future failures.

Conclusion

A non-functioning inverter fan is a critical issue that requires prompt attention. It not only affects the inverter’s own performance and lifespan but also poses risks to connected equipment and safety. Regular maintenance (e.g., dust cleaning, fan health checks) is essential to prevent such failures and ensure the reliable operation of inverter systems.