DC fans are vital for thermal management in electronics, industrial machinery, and consumer devices. While modern brushless models offer 50,000–100,000 hours of operation, strategic maintenance can extend this by 20–30%, ensuring reliability in critical applications. This guide distills professional techniques to optimize performance and longevity, rooted in engineering best practices.

1. Proactive Cleaning: Defending Against Dust & Debris

Dust accumulation is the primary threat to fan efficiency and lifespan, causing blade imbalance and bearing friction.

Step-by-Step Cleaning Protocol

- Blades & Grilles: Use a soft brush or low-pressure compressed air (≤30 PSI) to remove dry debris. For stubborn residue, wipe with isopropyl alcohol (avoid water to prevent corrosion).

- Bearings: Non-sealed bearings (sleeve/rifle) benefit from gentle debris removal with cotton swabs before relubrication; sealed bearings (ball/magnetic) only need external cleaning.

- Frequency: Clean every 3–6 months in dusty environments (data centers, workshops) and annually in clean settings (home electronics).

2. Precision Installation: Minimizing Mechanical Stress

Improper installation accelerates wear—follow these critical steps:

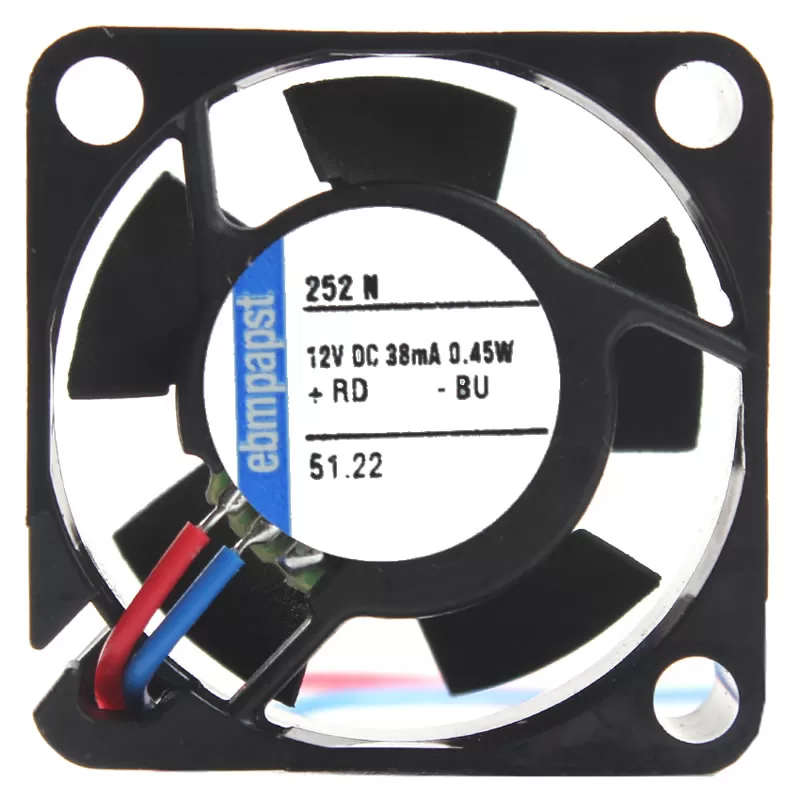

- Voltage Compliance: Use a regulated power supply within the fan’s rated voltage (e.g., 12V ±10%) to avoid winding damage from over/undervoltage.

- Vibration Isolation: Install with rubber mounts or anti-vibration screws to reduce resonance. Loose fans increase bearing stress by 30%.

- Airflow Alignment: Confirm intake/exhaust direction (intake grilles face cool air) to avoid motor overload, especially in high-static-pressure setups.

3. Bearing Care: The Lifespan Core

Bearings dictate 70% of fan life—maintain them based on type:

A. Non-Sealed Bearings (Sleeve/Rifle)

- Lubrication: Every 1–2 years, apply 1–2 drops of synthetic oil (e.g., ISO VG 32) to the bearing inlet. Avoid generic oils with abrasive additives.

- Caution: Over-lubrication attracts dust; wipe excess gently with a clean cloth.

B. Sealed Bearings (Ball/Magnetic)

- No Lubrication Needed: Factory-sealed designs require no oil. Replace immediately if grinding/clicking noises indicate ball wear.

C. Magnetic Levitation Bearings

- Maintenance-Free: Focus on shaft alignment during installation to prevent magnetic field distortion, which reduces efficiency by 10%.

4. Power Supply Optimization: Stable Energy for Sustained Operation

Voltage fluctuations and noise degrade motors—implement these solutions:

- Regulated Power: Use supplies with ≤5% voltage ripple (e.g., Mean Well LRS series) for critical applications to avoid winding overheating.

- EMI Filtering: Add ferrite beads to power cables to reduce electromagnetic interference, protecting motor controllers from premature failure.

- Battery Systems: Replace aging batteries promptly; voltages below the fan’s minimum rating force motors to work harder, increasing winding temperatures.

5. Vibration Control: Balancing for Longevity

Unbalanced fans lose 20% lifespan yearly—restore symmetry:

- Blade Balance: Spin by hand; add tiny adhesive weights (0.5–1g) to the opposite blade of heavy spots to eliminate uneven rotation.

- Secure Mounting: Retighten screws to manufacturer specs (0.5–1.0 N·m for 30mm screws) and use captive screws in server racks to prevent vibration loosening.

6. Routine Performance Checks: Early Fault Detection

Monitor key metrics to catch issues before failure:

- RPM Consistency: Use a tachometer to ensure speed stays within 10% of rated values; drops signal bearing wear or voltage problems.

- Noise Analysis: New rattles/whines indicate debris in bearings (clean) or misalignment (reinstall with shims).

- Temperature Monitoring: Motor housing temps >60°C (140°F) in non-ruggedized fans suggest overload—investigate blockages or voltage issues.

7. Storage & Handling: Preserving During Inactivity

Proper storage maintains fan condition during downtime:

- Pre-Storage Care: Clean thoroughly and lubricate non-sealed bearings to prevent grease drying.

- Environment: Store in cool (20–25°C), dry (<50% humidity) spaces; use anti-static bags for fans with electronic controllers to avoid ESD damage.

8. Smart Selection: Starting with Quality

Longevity begins with choosing the right fan:

- Bearing Types: Opt for ball/magnetic bearings (5–10+ years) for 24/7 use; sleeve bearings (3–5 years) suit lighter loads.

- IP Ratings: Select IP54/IP67 models for dusty/wet environments (e.g., ebm-papst EC fans) to protect against contaminants.

- Reliable Brands: Trust manufacturers like Delta, Noctua, or Nidec, known for rigorous testing (e.g., 5,000-hour burn-in trials).

Maintenance Log: Track for Success

Document services to identify trends and ensure accountability:

| Date | Action Taken | Observed Issues | RPM Before/After |

| 2025-05-11 | Cleaned + relubricated | Slight bearing hum | 1800 → 1900 RPM |

Advanced Industrial Techniques (Optional)

- Thermal Cycling: Test fans at -40°C to +85°C annually to detect expansion-related faults in automotive/industrial setups.

- Debris Monitoring: Use magnetic chip detectors in oil-lubricated fans to capture metallic particles (>50μm signals advanced wear).

Conclusion: The ROI of Proactive Care

A well-maintained DC fan outperforms expectations, reducing downtime costs and enhancing system reliability. By combining regular cleaning, precise installation, and smart bearing management, you’ll unlock extended lifespan and consistent performance—essential for today’s high-demand thermal environments. Start with a thorough inspection, apply these tips systematically, and let your fans deliver beyond specifications.