Whether a 12V DC fan can be used in extreme temperature environments depends on its design, construction, and the specific temperature range it needs to withstand. Here’s a detailed analysis of key factors and considerations:

1. Temperature Ratings of 12V DC Fans

Most standard 12V fans are designed for ambient temperatures between -10°C to 60°C (14°F to 140°F), suitable for typical indoor or automotive use. However, specialized models can handle broader ranges:

- High-temperature fans: Rated for 70°C–125°C (158°F–257°F), used in industrial ovens, engine compartments, or server rooms.

- Low-temperature fans: Designed for -40°C–0°C (-40°F–32°F), suitable for freezers, cold storage, or outdoor winter applications.

2. Key Components Affected by Extreme Temperatures

(1) Motor and Windings

- Standard motors: Use copper windings with thermoplastic insulation, which may soften or melt above 70°C, causing short circuits.

- High-temperature motors: Employ enamel-coated copper wire with higher thermal resistance (e.g., Class H insulation, rated for 180°C) or ceramic components.

(2) Bearings

- Sleeve bearings: Commonly use oil or grease that can dry out in high heat (above 60°C) or freeze in low cold (-20°C), increasing friction and noise.

- Ball bearings: More durable, with metal-on-metal contact that withstands -40°C–120°C, but may require temperature-rated lubricants (e.g., silicone grease for high heat).

(3) Housing and Blades

- Plastic components: Standard ABS or PVC may warp above 60°C or crack below -20°C.

- Heat-resistant materials: Polycarbonate (PC) or nylon for high temperatures; reinforced plastics or metal (aluminum) for cold environments.

3. Performance in Extreme Temperature Scenarios

(A) High-Temperature Environments (e.g., 80°C–120°C)

- Feasibility with specialized fans:

- Look for models labeled “high-temperature” or “thermal management,” which often have:

- Ball bearings with silicone lubricant.

- Metal or heat-resistant plastic housings.

- Motors with Class F/H insulation (155°C/180°C rating).

- Limitations of standard fans:

- Reduced lifespan: Lubricants degrade, motors overheat, and plastics warp, leading to failure within months.

- Efficiency drop: Airflow may decrease as motor resistance increases with temperature.

- Look for models labeled “high-temperature” or “thermal management,” which often have:

(B) Low-Temperature Environments (e.g., -30°C–0°C)

- Feasibility with specialized fans:

- Models designed for cold use feature:

- Ball bearings (less prone to freezing than sleeve bearings).

- Flexible plastics (e.g., thermoplastic elastomers) to prevent cracking.

- Pre-lubrication with low-viscosity grease (e.g., lithium-based) that remains fluid in cold.

- Risks with standard fans:

- Stalled operation: Lubricants thicken, causing the fan to seize up when powered on.

- Brittle components: Plastic blades may crack during startup due to reduced flexibility.

- Models designed for cold use feature:

4. Environmental Factors Beyond Temperature

- Humidity and Condensation:

- In high-temperature/humid environments, moisture can corrode motor windings. Look for fans with waterproof coatings (IP54/IP65 ratings).

- In cold environments, condensation may freeze on blades, reducing airflow or causing imbalance.

- Dust and Debris:

- Extreme temperatures in industrial settings (e.g., factories, engines) often coincide with high dust levels. Sealed bearings (ball bearings) resist debris better than open sleeve bearings.

5. Applications and Suitable Fan Types

| Environment | Temperature Range | Recommended Fan Features | Example Use Cases |

| Engine compartment | 80°C–120°C | Metal housing, ball bearings, Class H insulation | Car engine cooling, industrial boilers |

| Cold storage room | -30°C–0°C | Flexible plastic blades, low-viscosity lubricant | Freezers, pharmaceutical storage |

| Outdoor winter equipment | -40°C–10°C | Stainless steel components, anti-freeze lubricant | Snowplows, outdoor electronics |

| Server room (high heat) | 40°C–70°C | High-airflow ball bearing fans, heat-resistant PC housing | Data centers, network cabinets |

6. Tips for Using 12V Fans in Extreme Conditions

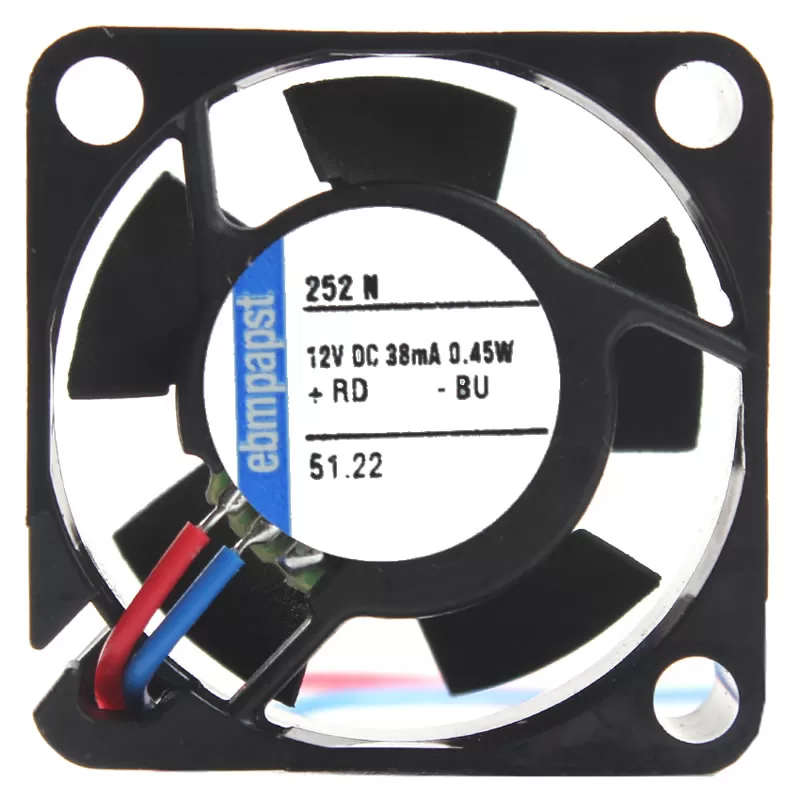

- Check manufacturer specifications: Verify temperature ratings, bearing type, and material composition before purchase.

- Test in advance: Run the fan in a controlled environment (e.g., oven or freezer) to ensure reliability.

- Implement safeguards:

- For high heat: Use a temperature sensor to trigger fan speed increases or shutoff if thresholds are exceeded.

- For cold: Preheat the fan briefly before use to fluidize lubricants (e.g., via a low-power pre-start cycle).

- Choose overrated components: Opt for fans rated 10°C–20°C beyond the expected maximum temperature for safety margins.

7. Limitations of 12V Fans in Extreme Scenarios

- Ultra-high temperatures (>150°C): Require specialized solutions like air-cooled or liquid-cooled systems, as even high-temperature fans may fail.

- Ultra-low temperatures (<-40°C): 12V fans may struggle due to battery performance issues (if powered by 12V batteries, which lose capacity in extreme cold).

Conclusion

12V DC fans can be used in extreme temperatures if they are specifically designed for such environments, with features like high-temperature insulation, durable bearings, and robust materials. Standard 12V fans are unsuitable for extreme conditions, but specialized models exist for industrial, automotive, or scientific applications. Always prioritize temperature ratings and component durability to ensure longevity and performance.