In modern telecommunications infrastructure, particularly in Ericsson’s advanced base stations and network equipment, continuous and efficient cooling is vital for ensuring stable operation and extending service life. As equipment power density continues to increase, the demands placed on cooling components become ever more stringent. In this context, fans conforming to the “BKV301 216/130” specification play a critical role. However, “BKV301 216/130” does not refer to a single specific product model, but rather a set of technical requirements defined by Ericsson for its high-performance cooling needs. Several top-tier fan manufacturers globally are capable of supplying fans that meet these requirements. Among the most recognized and widely used are specific models from Delta, NIDEC, and ebm-papst.

BKV301 216/130: A High-Performance Cooling Specification Standard

The BKV301 216/130 fans used in Ericsson equipment typically refer to DC axial fans with specific dimensions, power supply characteristics, performance levels, and intelligent control features. This is a standard set for demanding operating environments and high-density thermal management requirements. These fans commonly utilize the industry-standard 172x172x51mm frame size, which is extremely common in telecommunications and server equipment, facilitating design and replacement. Their core requirement is the ability to deliver significant airflow within a compact space and possess the capacity to generate considerable static pressure to overcome air resistance caused by heatsinks, cable bundles, and structural components within the equipment. The power supply is universally 48V DC, a standard voltage in the telecommunications industry.

Meeting the Standard: Key Players – Delta, NIDEC, and ebm-papst

To ensure supply chain robustness, competitive pricing, and leverage the technical strengths of different manufacturers, Ericsson typically procures fans meeting the BKV301 216/130 specification from multiple qualified suppliers. Among these, the following three models are most frequently referenced and utilized:

- Delta EHB1748EHG: As a leader in power and thermal management solutions, Delta’s fan is known for its high efficiency and reliability.

- NIDEC Y17L48BS2AA5-09E02: NIDEC has a deep technical heritage in precision motors and fans, with products known for performance and stability. The Y17L series represents their high-performance DC fans.

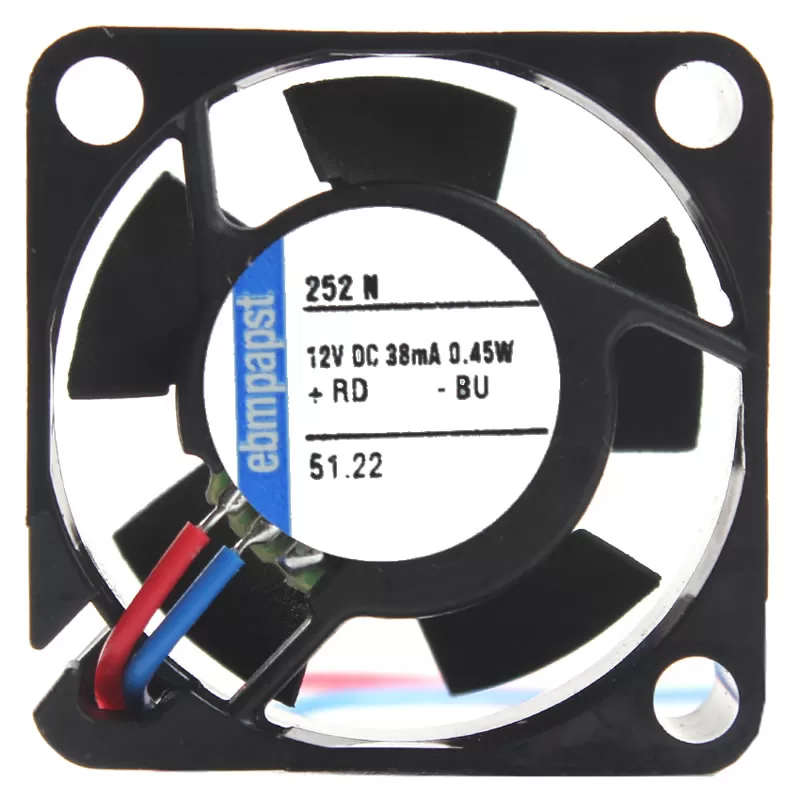

- Ebm-papst 6318/19HPU: Ebm-papst is considered a leader in fan technology, particularly in aerodynamics and overall system efficiency. The 6318 series is their high-performance DC fan range, with the HPU model specifically optimized for performance under pressure and environmental robustness.

Technical Parameter Comparison and Analysis: Cornerstones of Performance and Subtle Brand Differences

While these three fan models differ in manufacturer and specific model number, they share a set of core technical parameters to meet the BKV301 216/130 specification, while also exhibiting nuances reflecting their respective manufacturers’ design philosophies:

| Parameter Characteristic | Delta EHB1748EHG | NIDEC Y17L48BS2AA5-09E02 (or BKV301 216/130) | Ebmpapst 6318/19HPU | Analysis and Comparison |

| Manufacturer | Delta Electronics | NIDEC | ebm-papst | Three global leaders in fan manufacturing, strong technical capabilities. |

| Fan Type | DC Axial Fan | DC Axial Fan | DC Axial Fan | Basic type is consistent. |

| Dimensions (WxHxD) | 172 x 172 x 51 mm | 172 x 172 x 51 mm | 172 x 172 x 51 mm | Standardized size, highly interchangeable. |

| Nominal Voltage | 48V DC | 48V DC | 48V DC | Standard telecom/data center voltage. |

| Operating Voltage Range | Typical: 36V – 56V DC | Typical: 20V – 56V DC or 40V – 56V DC | Typical: 36V – 72V DC | NIDEC may have a wider starting voltage range. Ebmpapst has a very wide op range. |

| Rated Current | Approx. 0.9 A – 1.2 A | Approx. 0.80 A – 0.90 A | Approx. 0.625 A – 1.1 A | Current draw varies slightly, relates to performance and efficiency. 6318/19HPU typically 0.625A. |

| Rated Power Input | Approx. 43 W – 58 W | Approx. 38.4 W – 43.2 W | Approx. 30 W – 52.8 W | Power consumption differences reflect energy efficiency and performance focus. 6318/19HPU typically 30W. |

| Rated Speed | Approx. 4000 – 4300 RPM | Approx. 4000 – 4200 RPM | Approx. 4000 RPM or higher (some variants up to 9200RPM) | Speeds are similar, foundation for high airflow/pressure. |

| Maximum Airflow | Approx. 300 – 350 CFM (or 510-595 m³/h) | Approx. 280 – 320 CFM (or 476-544 m³/h) | Approx. 320 – 420+ CFM (or 544-700+ m³/h) | Ebmpapst and Delta often have higher maximum airflow. |

| Maximum Static Pressure | Approx. 250 – 350 Pa | Approx. 200 – 300 Pa | Approx. 300 – 400+ Pa or higher | Ebmpapst typically excels in static pressure capability, suitable for high-resistance systems. |

| Noise Level | Approx. 62 – 68 dBA | Approx. 60 – 65 dBA | Approx. 60 – 70+ dBA | Noise levels are generally high, directly related to performance. |

| Bearing Type | Ball Bearing | Ball Bearing | Ball Bearing | Standard for high reliability. |

| Connection Type | 4-Wire (FG/PWM) | 4-Wire (FG/PWM) | 4-Wire (FG/PWM) | Standard intelligent control interface, consistent functionality. |

| Expected Lifetime (L10) | Typically 50,000 – 70,000+ hours @40°C | Typically 50,000+ hours @40°C | Typically 50,000 – 80,000+ hours @40°C | Manufacturers may offer different specified lifetimes. |

| Frame Material | Die-cast Aluminum | Die-cast Aluminum | Die-cast Aluminum | Robust structure, good heat dissipation. |

| Impeller Material | Thermoplastic Plastic | Thermoplastic Plastic | Glass-fiber reinforced PA plastic etc. | Material choice can affect strength, weight, and aerodynamic performance. |

| Protection Rating (IP) | Varies by model, check datasheet | Varies by model, check datasheet | IP68 for 6318/19HPU (based on datasheets) | Ebmpapst 6318/19HPU has excellent dust and water protection. |

| Typical Protection Features | Lock protection, polarity protection, soft start, etc. | Thermal overload protection, lock protection, polarity protection, etc. | Lock protection, polarity protection, soft start, advanced electronic protection. | Comprehensive features, specific implementation may vary. |

| Operating Temp Range | Typical industrial range | Typical industrial range | -10°C / -20°C to +70°C / +75°C | Ebmpapst provides clear temperature ranges. |

Deeper Analysis and Brand-Specific Characteristics:

While these three fans share similar parameters, they exhibit different design philosophies and performance focuses:

- Delta: Known for strong manufacturing capabilities and extensive experience in power and thermal solutions. Delta’s fans often offer competitive performance for value and excel in high airflow. The EHB series is part of their high-performance line.

- NIDEC: Possesses deep technical knowledge in precision motors. Their fans are recognized for high efficiency, good motor control, and reliability. The Y17L series is NIDEC’s high-performance offering for server and telecommunications equipment.

- Ebm-papst: Often considered a leader in fan technology, particularly in aerodynamics and overall system efficiency. Ebmpapst fans typically excel in static pressure performance and energy efficiency, maintaining good airflow even against high system resistance. Their 6318 series is a classic high-performance compact DC axial fan range. The 6318/19HPU’s noted IP68 rating gives it a significant advantage in harsh environments.

Ericsson’s strategy of procuring fans conforming to the BKV301 216/130 specification from these three suppliers is a classic example of a multi-sourcing strategy. The benefits include:

- Supply Chain Security: Reduces reliance on a single supplier, mitigating the risk of supply interruptions.

- Cost Optimization: Drives competitive pricing by sourcing from multiple vendors.

- Performance Matching: Subtle differences in performance curves (especially airflow vs. static pressure), noise characteristics, environmental suitability, or functional details allow Ericsson to select the most precisely matched fan for different locations within their equipment or for various product models.

- Combining Technical Strengths: Leverages the specific technical advantages of each manufacturer.

Conclusion:

The fans used in Ericsson equipment conforming to the BKV301 216/130 specification are unsung heroes of high-density telecommunications reliability. They ensure the stability of critical infrastructure with their standard dimensions, powerful thermal performance, intelligent control interfaces, and long service life. The Delta EHB1748EHG, NIDEC Y17L48BS2AA5-09E02, and Ebmpapst 6318/19HPU are representative examples of excellent products that meet this stringent standard, each showcasing the technical prowess and engineering intelligence of their respective manufacturers in the high-performance DC fan market. Notably, the ebm-papst 6318/19HPU’s potential IP68 rating offers enhanced robustness for challenging environmental conditions. Ericsson’s decision to source from these three top-tier suppliers ensures the required cooling performance, reliability, environmental adaptability, and supply chain resilience for their communication equipment. To identify the exact model used in a specific piece of equipment, consulting that equipment’s bill of materials or the fan’s label is necessary.